Ammonia is Critical to Food Security

- Ammonia is the starting point for all mineral nitrogen fertilizers, forming a bridge between the nitrogen in the air and the food we eat.

- Approximately 85% of today’s ammonia is used to make agricultural fertilizers.

- Each IGP Ammonia plant will add ≈10% to US ammonia production capacity.

About 50 percent of the world’s food production requires mineral fertilizer. Due to the increasing world population, there has been a constant growth in fertilizer consumption over the last 50 years. As an important base material for fertilizers, ammonia is a critical resource for global food security.

Today, over 80% of the annually produced ammonia is used for fertilizer production. Fertilization improves plant nutrition, promotes plant growth, improves crop quality, and ultimately maintains and even enhances soil fertility.

Ammonia is also quickly gaining global attention as a carbon-free liquid combustion fuel and hydrogen-carrier for fuel cells that can reduce CO2, sulfur, and particulate emissions. The world is driving towards a lower-carbon future.

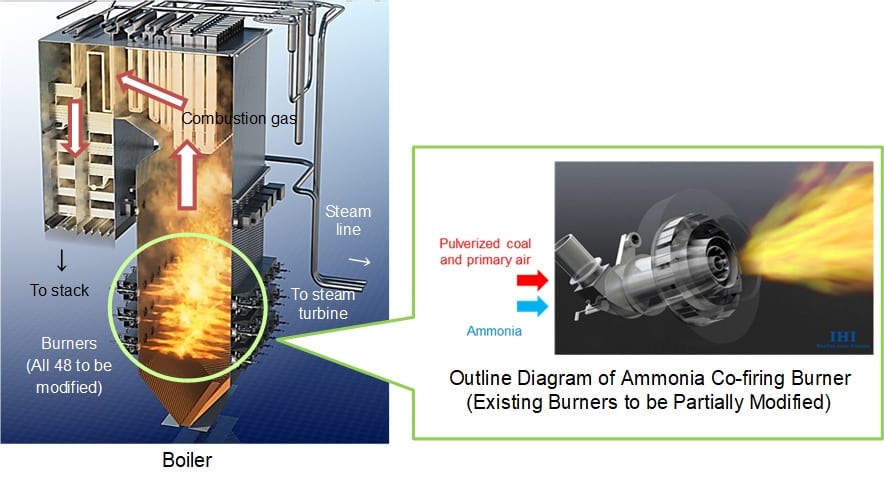

Japanese utilities are committed to blending increasing amounts of ultra-low carbon ammonia into coal-fired power plants to reduce CO2 emissions.

This diagram shows the outline of the boiler and the modified burner for the demonstration project at the Hekinan plant. Courtesy: JERA

Japan aims to reduce its greenhouse gas emissions to 46% of 2013 levels by 2030. Unlike many sources of energy, ammonia emits no carbon dioxide when burned. The Japanese government sees ammonia as a possible energy solution for a country that is wary of nuclear power and has few local options for renewable power.

The new policy could lead Japan to triple its annual ammonia consumption to 4 million metric tons (t) by 2030 Japan’s Ministry of Economy, Trade, and Industry says. By 2050, when Japan wants to convert all coal-fired power plants to ammonia, consumption could be 30 million t.

https://cen.acs.org/business/petrochemicals/Japan-run-ammonia/100/i14

The South Korean government has announced plans to burn vast amounts of hydrogen and ammonia for power production in the 2030s.

The Ministry of Trade, Industry and Energy (Motie) said it wants to use a fuel mix of 30% hydrogen at all its gas-fired power plants by 2035, and 20% ammonia (NH3) at more than half of its coal power stations as early as 2030, as part of its plan to reach net-zero emissions by 2050.

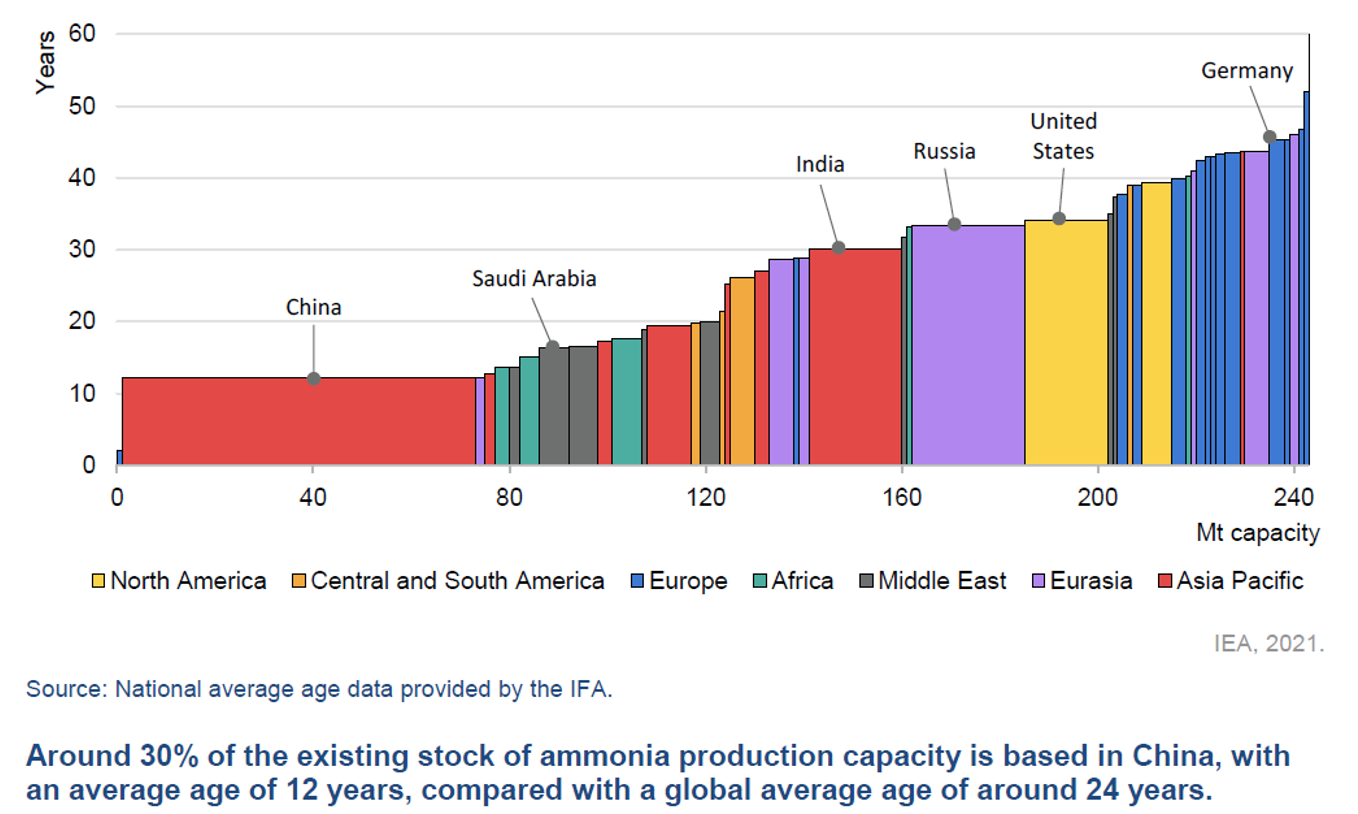

Ultra-Low-Carbon and Renewable Ammonia plants (sometimes referred to as “blue” and “green”) will displace older, more expensive plants with higher emission profiles. In fact, nearly 50% of the world’s ammonia production is 25-50+ years old and approaching middle to old age and will need to be replaced.

https://www.ammoniaenergy.org/articles/iea-publishes-ammonia-technology-roadmap/

Demand growth for ultra-low carbon ammonia is projected to outpace new production capabilities, while older ammonia plants are at risk of eventual closures due to natural gas constraints and/or high CO2 emissions. The United States is extremely fortunate to have both low-cost abundant natural gas as well as geological formations that can safely sequester CO2.

IGP Ammonia is developing its world-scale Ultra-low Carbon and Renewable Ammonia Facility in south Texas.

As CO2 emission regulations become stricter, carbon-free ammonia will have major strategic and cost advantages over the dirty competition and help our buyers meet corporate carbon pledges. IGP Ammonia, LLC will deliver the lowest carbon footprint of any industrial-scale ammonia production in the world. IGP is led by seasoned management and technical teams that have built and/or operated 60% of the methanol industry’s largest syngas conversion projects.

IGP is leveraging its experience developing comparable plants to fast-track this project, saving years and tens of millions of dollars.

- IGP’s team brings approximately 300 years of collective construction, operating, and financing experience in the energy sector.

- Technical and leadership experience in the construction management of methanol and natural gas liquids production facilities and in commercial structuring of energy development projects.

- Experience working with governmental agencies to acquire required permitting for construction of energy facilities.

- Experience negotiating contract terms with some of the largest ammonia buyers and C-level contacts.

Ultra-low carbon and renewable ammonia brings key strategic benefits to the global ESG efforts. This can be seen in the way this clean product impacts the objectives of the UN’s Sustainable Development program.

Per the International Energy Association, the Blue break through can contribute to achieving several of the United Nations Sustainable Development Goals (SDGs) by 2030, including the following:

SDG 2 – End hunger, achieve food security and improved nutrition, and promote sustainable agriculture: nitrogen fertilizers facilitate food production, and as such their production and use can contribute to ending hunger.

SDG 3 – Ensure healthy lives and promote well-being for all at all ages: since production and consumption of ammonia-based products is one of many contributors to air pollution, reducing pollutants can contribute to improved human health.

SDG 9 – Build resilient infrastructure, promote inclusive and sustainable industrialization and foster innovation: given that ammonia production is a part of the industrial sector, development and deployment of more sustainable technologies will contribute to the broader goal of sustainable industrialization.

SDG 12 – Ensure sustainable consumption and production patterns: improving the efficiency of use of nitrogen fertilizers and other ammonia-based products will contribute to improved resource efficiency and more sustainable consumption.

SDG 13 – Take urgent action to combat climate change and its impacts: since a substantial amount of greenhouse gases is emitted as a result of producing and consuming nitrogen fertilizers and other ammonia-based products, switching to near-zero-emission technologies and improving use efficiency will contribute to tackling climate change.

SDG 14 – Conserve and sustainably use the oceans, seas and marine resources for sustainable development: nitrogen fertilizer use contributes to nutrient pollution of waterways and oceans, and therefore more efficient use can improve the health of marine ecosystems.

SDG 15 – Protect, restore and promote sustainable use of terrestrial ecosystems, sustainably manage forests, combat desertification, and halt and reverse land degradation and halt biodiversity loss: since fertilizer use improves yields, more widespread use can reduce the land needed to produce the same amount of crops, and thus help reduce the need to convert natural ecosystems to agricultural production. Meanwhile, improving fertilizer use efficiency can help reduce ecosystem impacts that arise from air pollution.

SDG 17 – Strengthen the means of implementation and revitalize the global partnership for sustainable development: through finance and technology transfer related to sustainable ammonia production, the global community can help improve sustainability and well-being in emerging-market and developing economies.