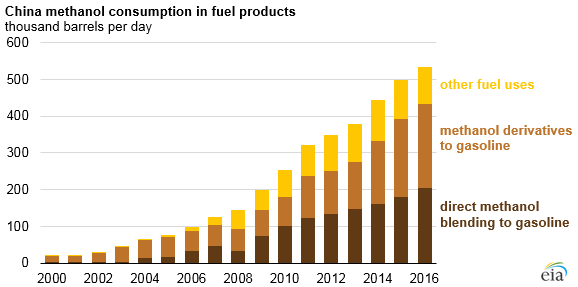

China is the global leader in methanol use and has recently expanded methanol production capacity. Since the early 2000s, China’s methanol consumption in fuel products has risen sharply and is estimated to have been more than 500,000 barrels per day (b/d) in 2016.

China is the global leader in methanol use and has recently expanded methanol production capacity. Since the early 2000s, China’s methanol consumption in fuel products has risen sharply and is estimated to have been more than 500,000 barrels per day (b/d) in 2016.

EIA commissioned a study from Argus Media group to better understand China’s consumption of methanol and its derivatives. The estimates developed in the study have now been incorporated into EIA’s historical data and forecasts of petroleum and other liquids consumption in China.

Methanol, like ethanol, is an alcohol with inherent issues such as its solubility in water and corrosiveness. Methanol or its derivative products can be added to fuels such as gasoline and liquefied petroleum gases (LPG). Similar to how ethanol is currently blended into motor gasoline in the United States, methanol is blended into gasoline in China.

Most of China’s methanol supply is from domestic production. About two-thirds of China’s methanol feedstock is produced from coal and the remainder from coking gas (a by-product of steel production) and natural gas. China has abundant coal resources, and for more than a decade the country has increased its capacity to manufacture methanol using coal as a feedstock. Smaller amounts of China’s methanol supply are imported from the Middle East, Southeast Asia, South America, and the United States.

Methanol is a clean-burning, high-octane fuel component, as the oxygen present in methanol aids in more complete fuel combustion. Blending methanol with gasoline allows refiners to extend China’s gasoline supply and increase the octane level of its gasoline. However, methanol has only one-half the energy per unit of volume as gasoline and requires more fuel consumption on a volumetric basis to provide the same amount of energy.

China’s largest city, Shanghai, and 13 of China’s 23 provinces have approved local standards for methanol blends ranging from 5% to 100% methanol. China has a national quality standard for methanol blends of 85%, and a national standard for a 15% blend of methanol in gasoline is pending approval by the government.

A methanol derivative known as methyl tertiary butyl ether (MTBE) is also blended into gasoline in China to increase octane levels. Consumption of MTBE and other derivatives in China was estimated at 230,000 b/d in 2016. Starting in the 1990s, MTBE was used as an oxygenate and octane enhancer in reformulated gasoline sold in the United States, with domestic production exceeding 200,000 b/d from 1998 to 2002. However, concerns over groundwater contamination led an increasing number of states to ban it. Following enactment of provisions of the Energy Policy Act of 2005 that were interpreted as reducing or eliminating legal defenses available to MTBE blenders, its use was soon phased out in the United States.

Methanol can also be converted directly to gasoline, and in China this conversion occurs much less often than the blending of methanol or its derivatives into gasoline. China built its first methanol-to-gasoline (MTG) plant in 2010, and since then, another 10 MTG plants have come online. MTG units involve high capital costs and are only cost-competitive when oil prices are high. Lower oil prices since late 2014 have reduced China’s MTG plant operating rates and have created uncertainty for investment in new MTG plants.

For blending into liquefied petroleum gases such as propane, China uses methanol to create a derivative known as dimethyl ether (DME), a compound that has the same molecular formula as ethanol but a different chemical structure. Despite an official ban on the use of DME in LPG cylinders, some DME has been blended into LPG delivered to China’s residential sector. Over the past two years, though, two factors—stronger enforcement of the DME ban and lower price competitiveness of DME relative to LPG—have reduced the level of DME blending.

Principal contributor: Candace Dunn